Have you ever been captivated by the rich, dark beauty of ebony wood? While its mesmerizing grain and smooth touch make it a dream for woodworkers, its reputation for cracking and instability can be daunting. Many people have told me they refuse to use it for fear of cracking. Fear not, fellow wood enthusiasts! Today, we delve into the fascinating world of ebony, exploring its unique properties and uncovering the secrets to unlocking its true potential, and how important the processing steps are.

As always, the secret culprit is wood moisture. One of the most important facets of wood that people always forget about. The main reason Ebony cracks is because of Wood movement due to changes in humidity. This involves drying the ebony down to ~10% moisture. These cracks are exacerbated by existing cracks which can act as propagation sites for new or larger cracks to form. This is about removing cracked areas, filling checks as they form and making sure the wood dries evenly and slowly.

At the heart of this art lies slow and deliberate drying.

Like many dense woods, rushing the process is a recipe for disaster. Snakewood is one of the best examples of this, as it is eager to form cracks. Most of the ebony when it arrives in the us is around ~25-35% moisture if its older stock, just due to higher ambient humidity in s.e asia or Africa. If you simply mill it into blocks and sell it quickly, this trapped moisture will inevitably escape, causing the wood to shrink and crack violently. The key is to control the drying of the wood, taking moisture reading over a few years and preventing swings in moisture. This means milling the large slab into smaller pieces to prevent warping before milling smaller blocks after the wood has passed the warping phase, as thin wood is more prone to shift. The process isn't fast; it takes years of careful monitoring and adjustments, ensuring the wood dries evenly and consistently.

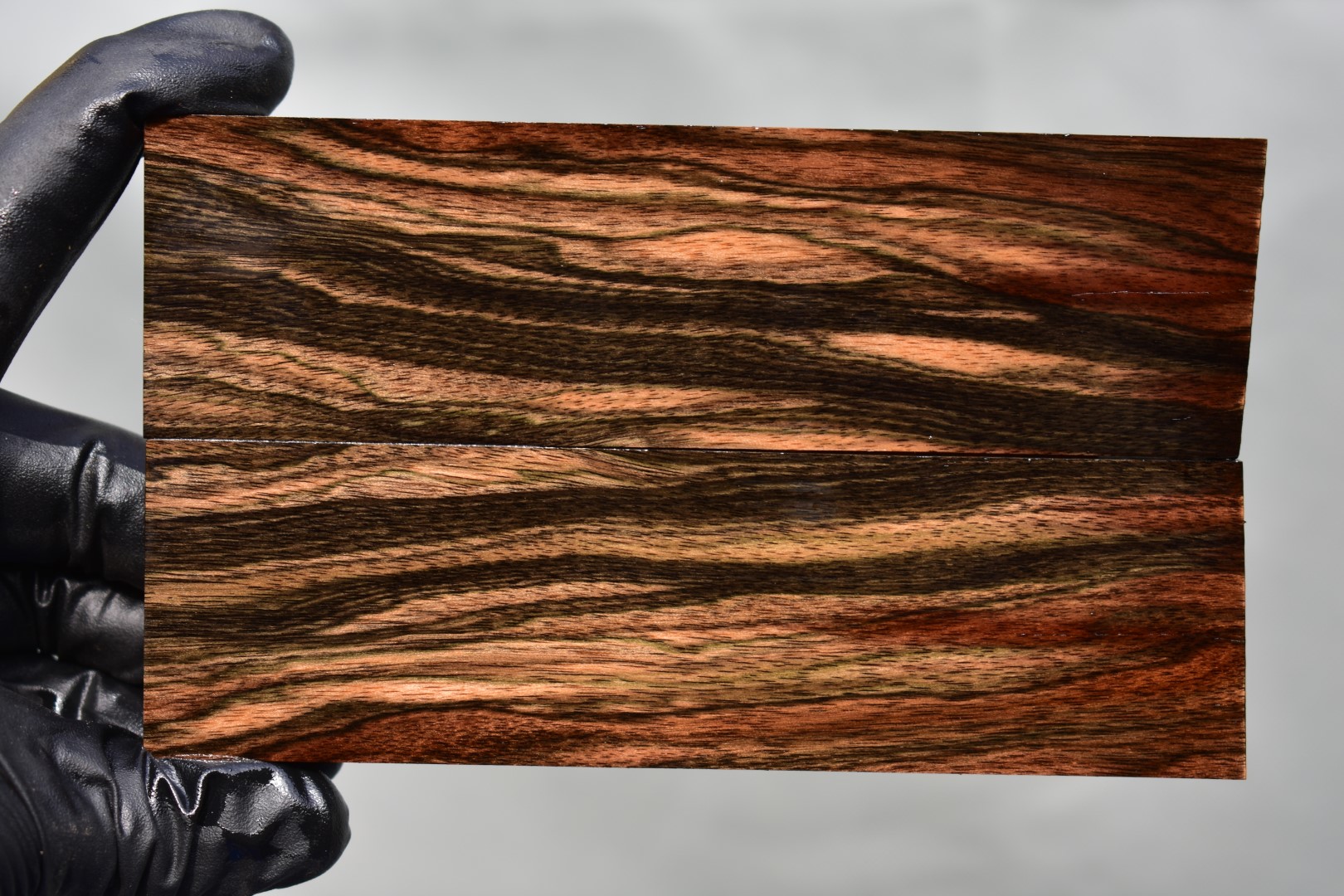

But drying alone isn't enough. We must also be ruthless in our inspection. Any early signs of cracks or checks are not to be ignored. They're like whispers of future failures, and we must act swiftly. Filling with CA glue or simply cutting them out is the best step. This means you are constantly reducing your yield of this already very expensive wood. It's a painful choice, but one that ensures the remaining wood is stable and crack-free, ready to become the foundation for stunning creations.Think of it a bit like cutting a gem, the flaws need to be removed while taking into account the grain of the wood. Will the resulting blocks be quartersawn and give an even, densely lined figure? Or flatsawn for more of a wild grain effect. How can voids be removed while still yielding the figure you want in the sizes that fit your customers?

This is the process that my ebony goes through, The mun ebony ive been selling arrived with me in early 2021 and is now ready for sale. Producing fine ebony is like producing a distilled spirit. It takes time of aging and drying and cutting and selecting. Does that make a wood snob? Yes absolutely. But ebony isnt my most profitable wood, its a wood I stock mostly because i am such a wood snob.

Knowing the details of how to prep ebony, the reason so much ebony is likely to check is that this process is a massive, expensive, slow pain in the ass. Most sellers want to get product in, mill it to final size and get it out the door. And that makes sense, thats a great business choice. But its not a great way to produce fine ebony. There are some pieces of advice to consider when buying ebony, that includes

Is it coming straight from a mill? If it arrives coated in wax, its almost certainly still wet. I advice being wary of the “Yeah its super old stock with a guy who had it 40 years” as this is the “This used car was only used to drive to church on sunday' ' of the wood world. It makes me sad to see, as I think a lot of my customers have had bad experiences with ebony and thus avoid whats really an incredible wood.

To really get the most out of your ebony, I recommend a few steps. First, buy high quality ebony. If it comes to you sealed all in wax, thats not dry. If it comes and within a day you see checking forming all around it, bad sign. Where is it coming from? Ambient humidity in asia is going to result and a baseline moisture of about ~20-25%

When the ebony arrives, I recommend storing it somewhere dark and away from the breeze for about a week. I ship from Socal where it tends to be dry, and so if you are in the PNW, ambient humidity may be a lot higher. A week or so to acclimate wil help a lot.

When working the ebony, use sharp blades and abrasives. High high can cause local cracking in any wood, but ebony partially. Dont leave the surface rough for long periods. A rough grain is full of sharp edges that can act as propagation sites for cracks to form. Before finishing for the day id recommend always getting ebony down to at least ~120 grit. Just not a ~60 grit finish. If you see any cracks form, use a little thin CA glue.True grit, Starbond and some others are all great CA glue. Filling cracks with a drip of CA glue will both hide it, and prevent it from spreading and propagating more cracks. And finally dont leave it in direct sunlight. That applies for a lot of wood, but you are more likely to get some checking in direct sunlight.

If you would like to try some of these ebony scales, they are up on my website, www.greenbergwoods.com